Accès à distance

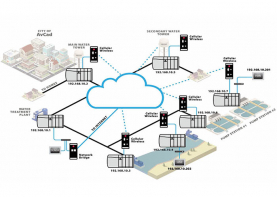

Transform Your Water and Wastewater Application’s Connectivity

Legacy connectivity in water and wastewater operations includes two major communication avenues: The DF1 industrial protocol, commonly seen in the industry; and the use of leased line modems to connect wide-ranging equipment. Discover how to update these on your timeline; the benefits their updated replacements can bring; and the role that industrial remote connectivity can play in water and wastewater applications.

Lire la suiteHow Utilities Benefit from Remote Connectivity

For utilities, remote connectivity offers the potential to limit field visits, reduce downtime, and more accurately collect information about usage and access. Learn about how utilities benefit from the technology and security features to consider.

Lire la suiteYour Most-Asked Remote Connectivity Questions

We’ve got the answers to your most frequently asked questions about industrial remote connectivity – including its security and how it works.

Lire la suiteLatest Belden Horizon Updates Prioritize Flexibility

New updates include on-prem deployment and Layer 3 IP Routing functionality. Get the details in this blog post!

Lire la suiteWhat You Asked About Most at Automation Fair: Modernization, Water and Wastewater Connectivity, and Protocol Conversion

Earlier this month, we got to go to the latest Automation Fair in Boston – this time a supersized one with learning opportunities to start and expo days to finish. Throughout the course of the show, we heard the latest situations that have you looking for connectivity solutions – check out this blog to learn about the three applications we heard about most.

Lire la suiteYour FAQs About Cloud-Based Networking Solutions

We’ve been hearing from more companies lately about how cloud-based networking solutions can be used in industrial applications – and most importantly, how they stay secure. Read this post to find out a few of the most frequently asked questions we receive about how cloud technologies can be used in industrial applications.

Lire la suite