In Oil and Gas? Find out how you can optimize production and decrease capital expenditures

In Oil and Gas? Find out how you can optimize production and decrease capital expenditures

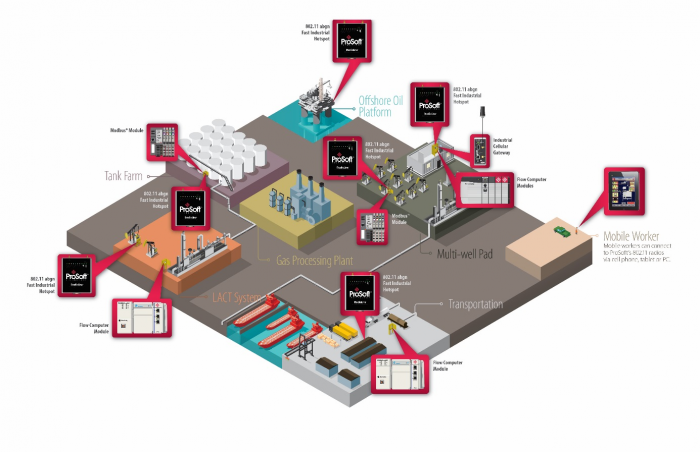

ProSoft Technology offers many solutions that help customers in the Oil and Gas industry improve operations and reduce capital expenditures, in addition to other benefits.

ProSoft’s 802.11abgn WiFi technology increases flexibility at the well pad site by providing data rates that meet or exceed the wired equivalent (up to 300 Mbps) while reducing capital expenditures by eliminating the cost to trench and run Ethernet cables to remote drops. This allows you to utilize distributed I/O directly at the well head location, at tank batteries, and back to central control rooms. With features not found in any other wireless products, such as status and diagnostic data available via EtherNet/IP™ or Modbus® TCP, commissioning and setup times are reduced while giving unprecedented diagnostic information of your wireless network directly in your automation controller and SCADA application.

By utilizing ProSoft’s Modbus module for Rockwell Automation’s POINT I/O™ platform, you can further eliminate costly and troublesome cable runs by placing your Modbus communication near the location of multivariable transmitters and tank level transmitters. Further cost savings can be utilized by incorporating this design with manufactured control cabinets, allowing for flexibility at the well pad site, and the ability to change out I/O as the needs of the facility are changed. With Premier Integration components to the Rockwell Automation® architecture, such as Add-On Profiles and Add-On Instructions, setup and configuration of Modbus networks is streamlined.

In addition, our In-Chassis Flow Computers allow your operations team to augment the Rockwell Automation PAC architecture and provide an industry-compliant flow computer application. With the ability to perform AGA and API flow calculations, and archive this information per specifications required for flow measurement, gone are the days of requiring a PLC/PAC for Control Operations and a separate system for Oil and Gas Flow Measurement.

Finally, the Industrial Cellular Gateway provides remote access to locations where you do not have communications by utilizing cellular networks. Now you can have access to critical data for production and process measurement anywhere you have cell phone coverage. With our ProSoft Connect cloud-native platform, remote access for debugging, troubleshooting, and maintenance is recognized without the need to install additional drivers on your PC, eliminating a common security flaw with other remote access solutions on the market today.

At ProSoft Technology, we are dedicated to finding innovative ways to increase production, reduce capital expense for completion costs, and provide greater accessibility to data than ever before. Our communication solutions and wireless technology provide all the tools you need to have more efficient operations.