Keeping currents safe for aluminum supplier

By Lauren Robeson

Many people use something that’s aluminum-based fairly often. Whether you’re drinking a canned beverage or covering a dish, chances are you’re not thinking of how the material came to be produced.

The process of aluminum production is a long and potentially hazardous one if precautions are not in place. Clauser Dunkerque, a company based in France, knows the challenges involved and the precision required, and set about to strengthen communications in the aluminum production process for a supplier in the Middle East.

Clauser Dunkerque primarily manufactures high-current conductors and special machinery for use in aluminum production. In this case, it was manufacturing an earthing trolley for the company, and it needed to ensure strong, clear communications. The device is used in a facility filled with potlines. These reduction pots hold extracted aluminum, and are electrically connected in a series. Once in the pots, the aluminum melts down and is divided. A potline can feature 1,000 or more pots in some cases, with high current to match.

With such a high-current application, it’s important to ensure that any potential leaky current is taken care of as soon as possible. A leakage can be caused by a variety of factors, including an insulation fault or humidity. In the best-case scenario, a leak left unfixed causes energy loss – and potentially losses in productivity and profit. Worst-case scenario, this can be hazardous to workers and cost a lot of money – if one flash occurs due to an unexpectedly high current, it could kill the substation, costing the company 100 million to 200 million euros.

So clear communications are a must in this type of facility. But they can be tricky: Running wires or cables from inside the potline to an outside environment wasn’t possible in this operation. And even some wireless radios could face an issue if used in the facility thanks to interference caused by electrical noise. Previously, the communications were hard wired to FLEX™ I/O and had to be connected and unconnected every time the trolley was moved. That led to maintenance issues, with connectors being damaged, and did not allow for monitoring of the current.

That’s where ProSoft Technology came in.

“We already had a business relationship with ProSoft Technology,” said Clauser Dunkerque Project Manager Fréderic Vervelle, who had worked with Feby Mohammed and Aurélien Fabre of ProSoft’s EMEA office in the past. “We also liked that local support was available.”

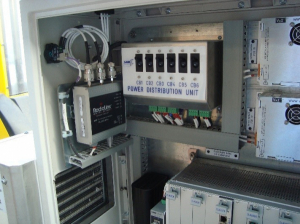

ProSoft Technology’s Weatherproof and Industrial Hotspot radios were used with MIMO antennas in conjunction with a Rockwell Automation® ControlLogix® system. The Weatherproof radios are perfect for this rugged application, and the 802.11n MIMO and channel bonding allows for high-resolution video monitoring while the I/O is being controlled – ideal for this application, where real-time information is crucial. The Industrial Hotspots offer Ultra-Fast access point switchover times of less than 10 ms, which came in handy as the earthing trolley connected to the closest repeater. Two master radios connected on different channels to avoid interference and ensure redundancy between the repeaters.

“Our on-site tests went well. We especially liked that the system was flexible with reduced configuration – it took just half a day to configure the radio system, and less than a week for the full deployment of the application,” Mr. Vervelle said. “We also like that ProSoft’s solution was approved by the Telecommunication Regulatory Authority – if it hadn’t been, we would have had declaration fees and a bandwidth-based payment.”

Now this reliable communications network helps ensure safe division and processing of aluminum.

Find out more about ProSoft Technology’s Industrial Wireless Solutions at http://psft.com/BU5.