Reduce Energy Usage by Connecting Building Automation Equipment

Reduce Energy Usage by Connecting Building Automation Equipment

Data from your facility’s equipment like boilers, chillers, HVAC systems, air compressors, generators, and more can help you identify inefficiencies. These building automation systems give you a sense of how much energy you’re using – and at what points you can cut energy usage, which will in turn help decrease energy costs.

The benefits aren’t just financial, though. Many companies are aiming to use energy in a more sustainable way. Whether that’s an internal goal or one tied to a public initiative such as an ESG (environmental, social, governance) campaign, collecting relevant data from these systems is a must. In addition, some countries’ regulations mean that this data must be maintained to show usage is at or below set limits, or to show decreased usage over time.

How the Data Could Help

How this data could help improve your facility’s sustainability efforts depends on the equipment your facility has. But to give you some ideas, data could help you detect:

· Opportunities to reduce energy usage, including ensuring electricity used to create compressed air isn’t wasted

· Excessive lighting or air conditioning usage when staffing levels don’t require it

· Holes in equipment causing lost resources

In addition, your equipment’s data could also help with predictive maintenance; as an example, if you know how many times a motor is turned on, you can gauge when you next need to change its gears.

Typical Protocols Used in Building Automation Equipment

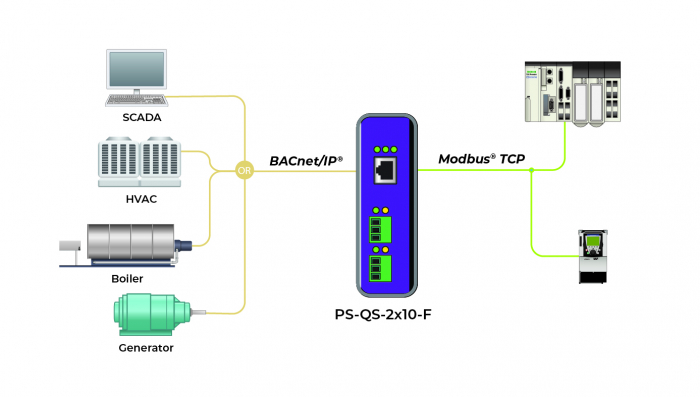

Much like in many areas of your facility, this type of equipment typically uses different protocols than your control system. Common protocols for building automation systems include BACnet, LonWorks, and Metasys.

Protocol converters – such as industrial standalone gateways – can help you connect the devices directly to your control system, ensuring the data gets to a location where you can analyze usage and identify inefficiencies.

Contact us to learn more about options for your building automation equipment.